PIPE ELBOW

LONG RADIUS ELBOWS, SHORT RADIUS ELBOW, CARBON STEEL ELBOWS, STAINLESS STEEL ELBOW MANUFACTURER

A234 WPB, A420 WPL6, A234 WP11, A234 WP5, A403 WP304L, A403 WP316L | ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43

LONG/SHORT RADIUS ELBOWS – 90° ELBOW, 45° ELBOW, 180° ELBOW, 1D, 2D, 3D, 4D, 5D, 10D, CUSTOM RADIUS ELBOWS

Carbon Steel Elbows, Stainless Steel Elbows, Alloy Steel Elbows, Long Radius Elbows, Short Radius Elbows. 3D Elbows, 5D Elbows, Custom Radius Elbow Supplier in India, 316 Elbow, A234 WPB Elbows Manufacturer, A420 WPL6 Elbow, A234 WP11 Elbow, A234 WP5 Elbow, A403 WP304 Elbow, A403 WP304L Elbow, A403-WP316 Elbow, A403-WP316L Elbow, Seamless Elbows, Large Diameter Fabricated Elbows, 20″ NB Elbow,36″ NB Elbow Supplier, Buttweld Elbows Manufacturer, Duplex 2205 Pipe Elbow, 100% X-Ray Welded Elbows

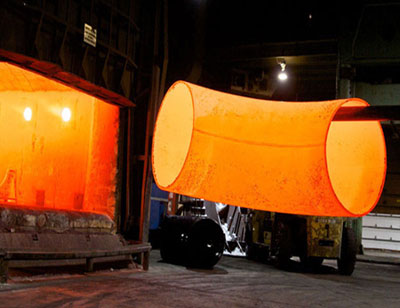

An ISO 9001:2008 Certified Company, Metline Industries is a leading manufacturer and supplier of short radius and long radius elbows. We offer our materials with complete certifications and as per international standards. Our production range includes stainless steel elbows, carbon steel elbows, alloy steel elbows, and elbows in special alloys such as Monel, Inconel, Hastealoy. We can manufacture elbows upto 48″ with wall thickness ranging from 1.5 mm thickness up to 40mm for varied sizes.

An elbow is a pipe fitting which is used as a connection point between two lengths of pipes to produce a change in the direction of flow in the pipe, usually at an angle of 90°, 45° or 180°. Elbows are also commonly referred as bends, and are available in a range of materials such as stainless steel, carbon steel, alloy steel, nickel alloys, duplex, and cupro nickel.

Also known as 90° bends, 90° elbows are manufactured as SR (Short Radius) elbows and LR (Long Radius) elbows. 45° elbows are typically made as LR (Long Radius) elbows.

The long radius elbows have a center to end distance that is 1.5 times the NPS in inches (R=1.5D), while the short radius is equal to the NPS in inches (R=1.0D).=Short radius elbows are generally used in tight areas, and long radius elbows are used when space is available and flow is more critical. We can also manufacture and supply carbon steel elbows and stainless steel elbows in non-standard size angles such as 60°, 100°, 120° or 150°.

The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

We are a high quality manufacturer and supplier of long radius elbows, short radius elbows, stainless steel elbows, duplex elbows, and carbon steel elbows as well as fabricated stainless steel elbows. We supply our products to customers in various industries including pharmaceutical, chemical, power, petrochemical, engineering and various other industries.

Our products – stainless steel elbows, carbon steel elbows and alloy steel elbows are regularly exported to Brazil, South Africa, UAE, Bahrain, Italy, Indonesia, Malaysia, United States, Mexico, Chine, Brazil, Peru, Nigeria, Kuwait, Jordan, Dubai, Thailand (Bangkok), Venezuela, Iran, Germany, UK, Canada, Russia, Turkey, Australia, New Zealand, Sri Lanka, Vietnam, South Africa, Kazakhstan and Saudi Arabia, Oman.

We distribute our products – stainless steel elbows, carbon steel elbows and alloy steel elbows across all major cities and industrial areas in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Buttwelded Pipe Elbow Production Range

| Outside Diameter: | Seamless Elbow ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″) |

| Wall Thickness: | 3mm – 40mm / SCH3, SCH10, SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Bending Radius: | R=1D – 10D, 15D, 20D |

| Product’s Angle: | 5° – 180° Elbows, 90° and 45° Long Radius Elbows, Long Radius Returns, Short Radius Elbows and Returns |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards

| ASME: | ANSI B16.9, ANSI B16.28, MSS-SP-43 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

| ASTM A403 – ASME SA403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.25 | Buttwelding Ends |

| ASME B16.28 | Wrought Steel Short Radius Elbows and Buttwelding Returns |

| MSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

Pipe Elbow Material Grades

| Stainless Steel Elbow | ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Carbon Steel Elbow | ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. |

| Low Temperature Carbon Steel Elbow | ASTM A420 WPL3, A420 WPL6 |

| Alloy Steel Elbow | ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Duplex Steel Elbow | ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Werkstoff No. 1.4462 |

| Nickel Alloy Elbow | ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) |

Marking & Packing

Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All elbow fittings are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our products.

Quality Assurance

At METLINE, all fittings and flanges are subject to strict inspection at each stage of the production process, from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM, ASME, MSS, DIN, EN, and JIS codes and standards. Upon request, official certified Inspection Agencies can be called in to witness the material reports, dimensions and quality conformity of products.

Test Certificates:

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report